The indBox system

Clever solution for production flow management

indBox is the solution for the handling of the parts inside the company, along the whole production process, and outside, during the transport and distribution phases of the finished products.

The tridimensional fixing system fastens and holds the parts during all the production phases: treatment, washing, quality control, storage and transport.

The tridimensional fixing system fastens and holds the parts during all the production phases: treatment, washing, quality control, storage and transport.

indBox is ideal for machining operations with engineered robotic cells as it avoids the risk of damage of the workpieces placed in it.

indBox is ideal for machining operations with engineered robotic cells as it avoids the risk of damage of the workpieces placed in it.

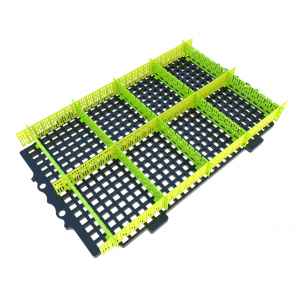

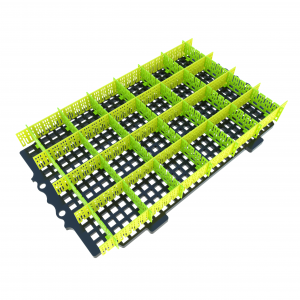

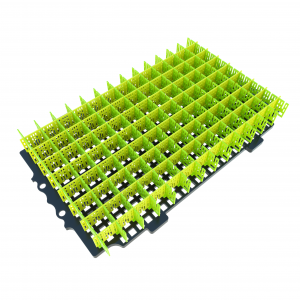

Thanks to the modular grid as well as the movable compartments and inserts to be placed on the horizontal and vertical axes, indBox allows maximal versatility to personalize the system according to placement needs of the workpieces.

Thanks to the modular grid as well as the movable compartments and inserts to be placed on the horizontal and vertical axes, indBox allows maximal versatility to personalize the system according to placement needs of the workpieces.

Storage and transport of the products shall occur in the same box in which they have been processed.

Storage and transport of the products shall occur in the same box in which they have been processed.

indBox is equipped with a RFID device which enables to check on the production progress, batch, quantity and position of the pieces management, by fitting it to the purpose of the most advanced production systems.

indBox is equipped with a RFID device which enables to check on the production progress, batch, quantity and position of the pieces management, by fitting it to the purpose of the most advanced production systems.

Resistant to impacts, durable, practical and light, indBox is a system designed to optimise production flows and to eliminate non-definitive packages.

Resistant to impacts, durable, practical and light, indBox is a system designed to optimise production flows and to eliminate non-definitive packages.

Integrated traceability system,

to follow and support the whole production process.

- quantity inside each box;

- production batch;

- progress of the workings.